Water Treatment Equipment with EDI

RO Water Treatment EquipmentPRODUCT PARAMETERS

|

model |

Water yield T/H |

Electric power KW |

Recovery % |

Primary effluent conductivity us/cm |

Secondary effluent conductivity us/cm |

EDI effluent conductivity us/cm |

Raw water conductivity us/cm |

|

ROC-500 |

0.5 |

0.75 |

55-75 |

≤10 |

2-3 |

≤0.5 |

≤300 |

|

ROC-1000 |

1.0 |

2.2 |

55-75 |

≤10 |

2-3 |

≤0.5 |

≤300 |

|

ROC-2000 |

2.0 |

4.0 |

55-75 |

≤10 |

2-3 |

≤0.5 |

≤300 |

|

ROC-3000 |

3.0 |

5.5 |

55-75 |

≤10 |

2-3 |

≤0.5 |

≤300 |

|

ROC-5000 |

5.0 |

7.5 |

55-75 |

≤10 |

2-3 |

≤0.5 |

≤300 |

|

ROC-6000 |

6.0 |

7.5 |

55-75 |

≤10 |

2-3 |

≤0.5 |

≤300 |

|

ROC-10000 |

10.0 |

11 |

55-75 |

≤10 |

2-3 |

≤0.5 |

≤300 |

|

ROC-20000 |

20.0 |

15 |

55-75 |

≤10 |

2-3 |

≤0.5 |

≤300 |

1. High water quality: It can remove almost all ions, organic matter, microorganisms and other impurities in water, meeting the needs of industries with extremely high water quality requirements such as electronics, pharmaceuticals, and chemical engineering.

2. Stable and reliable operation: High degree of automation, easy operation, no need to add chemicals during the operation process, avoiding water quality fluctuations and equipment corrosion caused by incorrect addition of chemicals.

2. Stable and reliable operation: High degree of automation, easy operation, no need to add chemicals during the operation process, avoiding water quality fluctuations and equipment corrosion caused by incorrect addition of chemicals.

3. Environmental protection and energy conservation: Compared with traditional ion exchange technology, EDI does not require acid-base regeneration, reduces chemical use and wastewater discharge, and is more environmentally friendly.

4. Small footprint: The equipment is compact and occupies a small area, making it suitable for places with limited space.

4. Small footprint: The equipment is compact and occupies a small area, making it suitable for places with limited space.

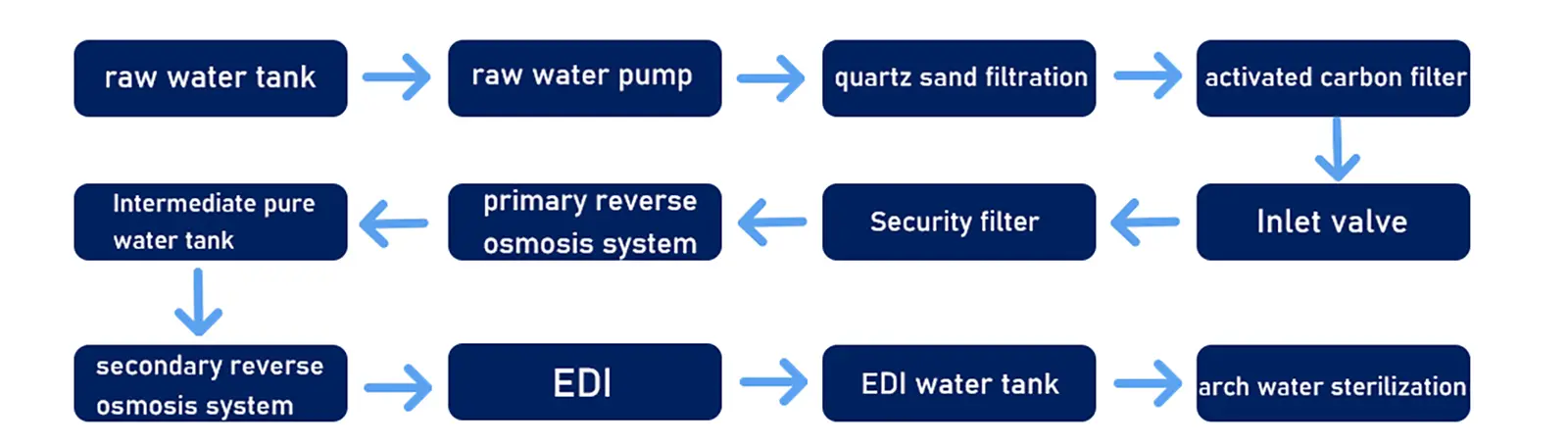

Working Process

external requirements

1.Inlet flow:water for operation≥6.0m3/h;

2.Recoil water:About 6.0 m3/h;

3.Power Supply: Power Conditions 380V/4ph/50Hz;

4.Total power capacity approx.:10Kw;

2.Recoil water:About 6.0 m3/h;

3.Power Supply: Power Conditions 380V/4ph/50Hz;

4.Total power capacity approx.:10Kw;

Product Applications

1. In the electronics industry, during the manufacturing of electronic components such as integrated circuits, semiconductors, and liquid - crystal displays, ultra - pure water is used for various procedures like cleaning, photolithography, and coating.

2. For the pharmaceutical industry, when manufacturing drugs, pharmaceuticals, and injection water, the demand for water quality is highly exacting. The EDI equipment for ultra - pure water can provide solutions that are in line with the standards of the pharmacopoeia.

3. In the chemical industry, ultra - pure water is employed in processes including the production of chemical products, reactions, and cleaning.

4. In the energy industry, there are thermal power plants, nuclear power plants, and other energy - related facilities.

2. For the pharmaceutical industry, when manufacturing drugs, pharmaceuticals, and injection water, the demand for water quality is highly exacting. The EDI equipment for ultra - pure water can provide solutions that are in line with the standards of the pharmacopoeia.

3. In the chemical industry, ultra - pure water is employed in processes including the production of chemical products, reactions, and cleaning.

4. In the energy industry, there are thermal power plants, nuclear power plants, and other energy - related facilities.